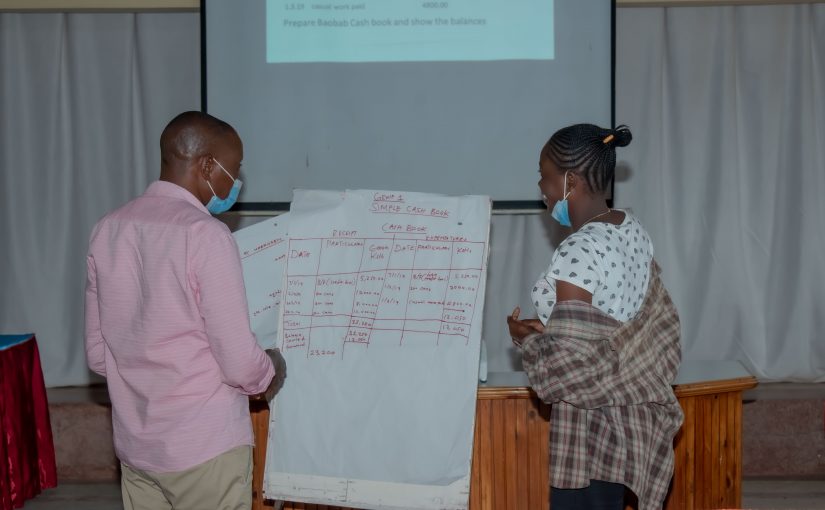

Project leader Prof. Dietrich Darr from Rhine-Waal University of Applied Sciences presented the work under the BAOQUALITY project at the XV World Forestry Congress 2022 in Seoul, South Korea.

The World Forestry Congress is one of the most influential conference in forestry. It serves as the global platform to issue recommendations and declarations on major forest issues worldwide. This year’s theme was “Building a Green, Healthy and Resilient Future with Forests”.

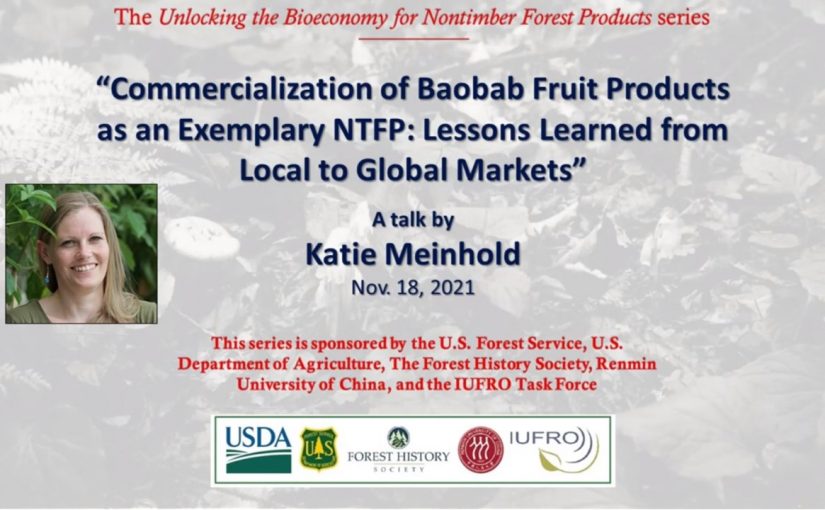

Prof. Darr’s talk was part of the side event ‘Framework to Expedite Transition to Bioeconomy with Nonwood Forest Products’, hosted by IUFRO, the Forest History Society and the US Forest Service.

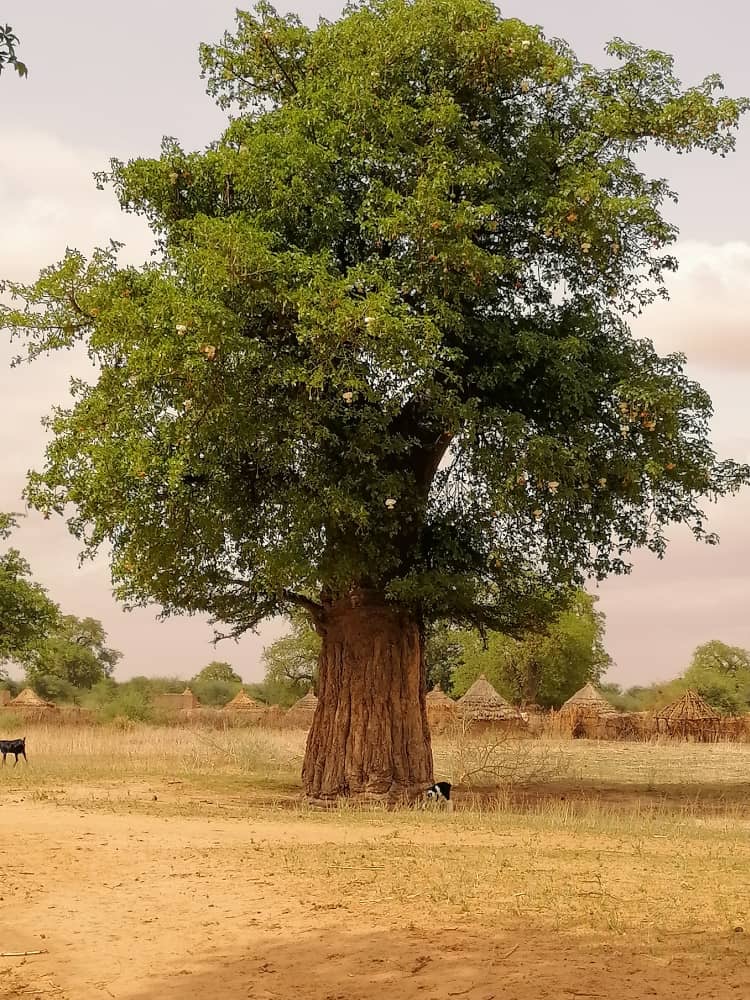

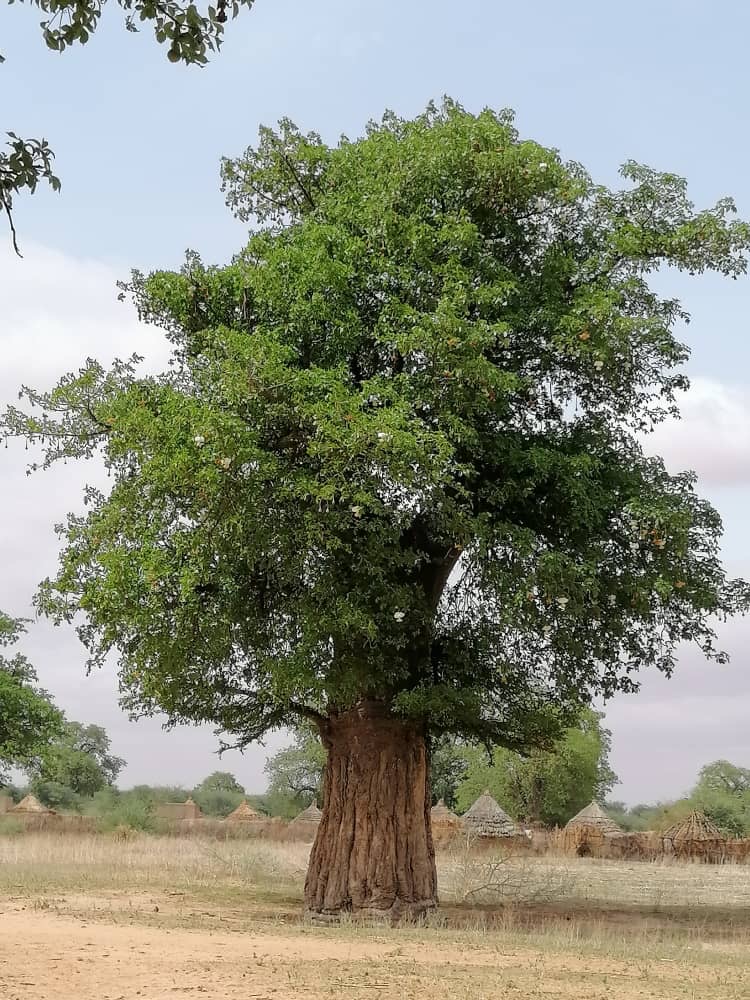

Prof. Darr used the research under the BAOQUALITY project to demonstrate how baobab products, as example for nontimber forest products, can enhance the bioeconomy transition in Malawi. He highlighted the potential of baobab biomass to use as renewable energy source, showed the multiple baobab-based products currently in use and illustrated the potential for further high-value products. He discussed key challenges for the proliferation of baobab products and innovations, which are related to profitability, acceptance, environmental and social impact, value chain structure and functioning as well as policy and institutional support.